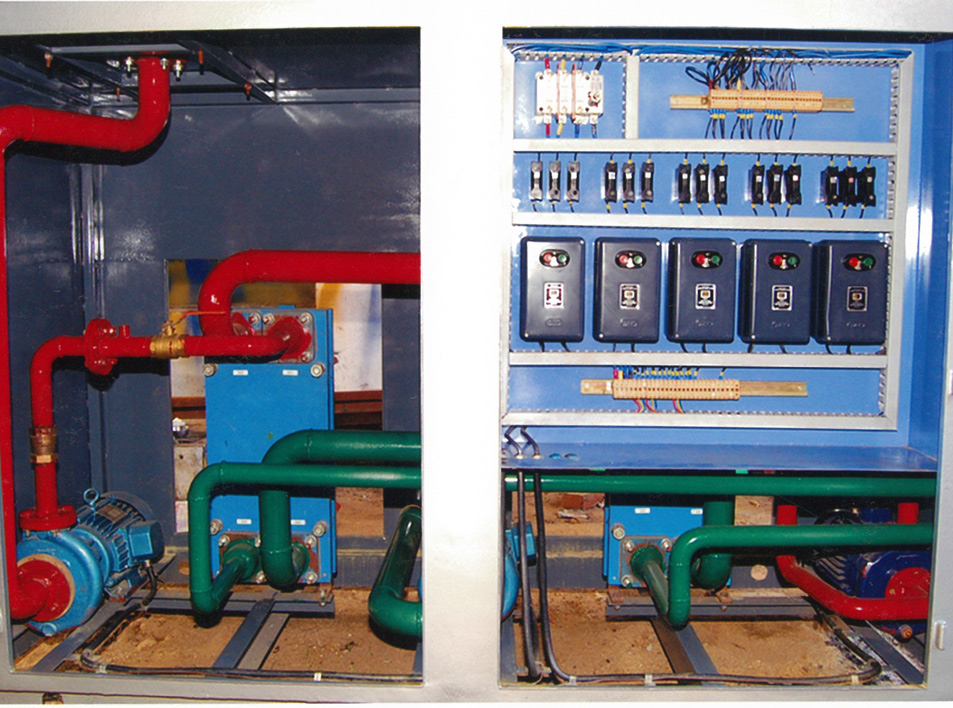

Induction Power Panel

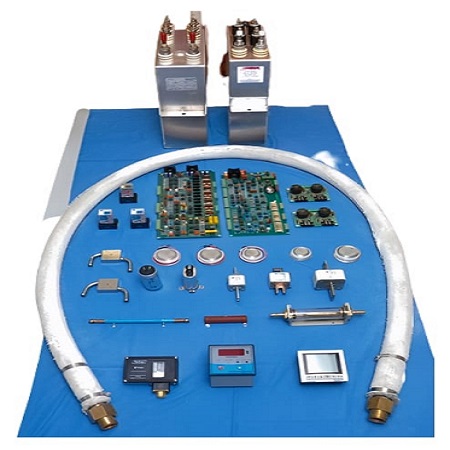

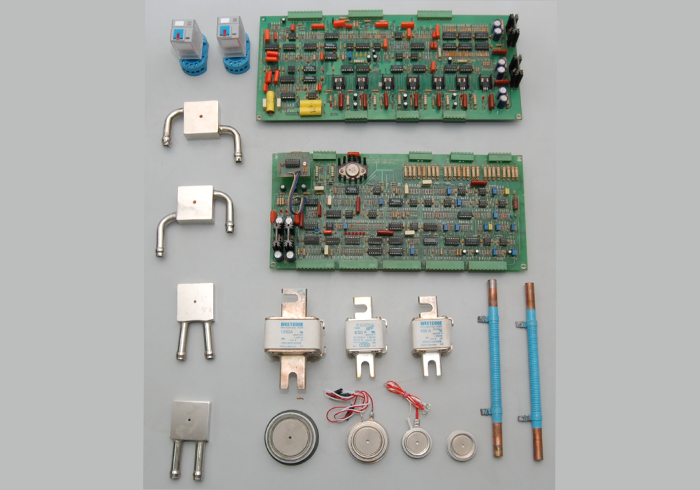

Fluxo power supply for medium frequency induction melting systems are designed and developed with a view to eliminate equipment breakdown problems and our rate of success in it is near to total. The ranges of power supplies are 50kW to 1500kW at 200Hz to 3000Hz frequency based on the requirement of the customer. The technology adopted by fluxo for its power supply is Voltage Fed system. This is to ensure very good power factor and the least power unit consumption. The power supply system is protected against over voltage, over current ground leakage etc., by fast acting electronic control circuits. Detailed display arrangements has been provided to monitor the operation of the power system and furnace through out the melting cycle.